RTape

RTape is recognized as the world's leading manufacturer of application tape and premasks for the sign, screen printing and digital printing marketplaces. The RTape product offerings also include decorative vinyl films, overlaminates, print media, paint mask and other auxiliary graphic arts products.

RTape Conform® with RLA®

RTape Conform® is the original application tape with RLA® Release Liner Adhesion. With RLA, RTape Conform sticks to slick release liners so tapes do not "dog ear" and stick together.

RTape ApliTape™

The sign maker's paper application tape for dependable, user-friendly performance at an affordable price.

RTape Clear Choice®

RTape Clear Choice® is a clear application tape that provides exceptional performance and versatility for the widest range of sign applications.

RTape Premask and Prespacing Tapes

Heavyweight paper tape solutions engineered with specific adhesive systems for the most common or challenging signage applications.

HotMask

HotMask® series of self-wound polyester transfer tapes are designed to protect printed heat transfer material from the high temperatures of heat pressing. Available in different tack levels, HotMask® transfers print and cut graphics from the carrier film and aids alignment of the graphic to the garment.

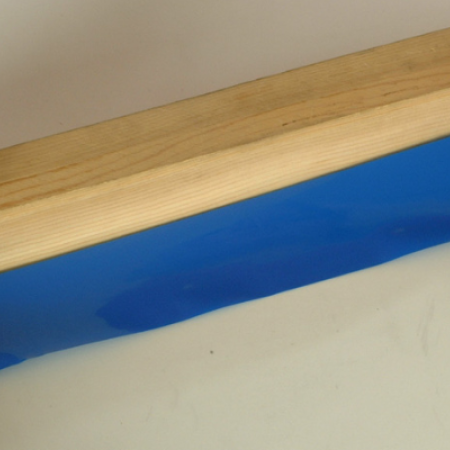

RTape Block Out Tape

Blue self-wound polyethylene film with aggressive acrylic adhesive to use with conventional wooden framed screens. Forms solvent-resistant ink dam preventing leakage. Removes cleanly from mesh without leaving adhesive residue. Taping both sides of the screen withstands multiple washings.

RTape Pallet Protek

Pallet Protek is a standard weight saturated smooth paper tape with heat resistant adhesive. Cleaning up messy spray adhesive from your pallet is time consuming and costly. It’s also unnecessary. By covering your pallet with Pallet Protek™ and spraying the paper tape instead of the pallet, press clean up time is simply a matter of removing and discarding the tape. The whole process is fast and easy.